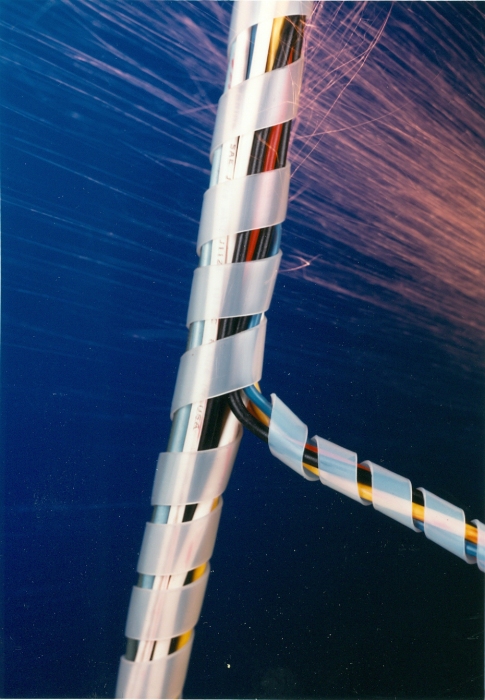

It’s versatile and flexible, capable of organizing cables or wires while protecting them from abrasion. Also known as spiral wrap or spiral tubing, spiral cable wrap is commonly utilized for electrical work to keep bundles of cabling organized. Unlike cable ties, spiral cable wrap doesn’t stress wiring bundles by pressing against them. They’re also useful in situations where cables need to be moved frequently. Since they can come in a variety of colors, it can help identify bundles of wires.

All these features of spiral cable wrap make maintaining cabling easier. Their spiral structure enables breakouts of single wires to specific equipment, while also allowing easier rerouting of cable bundles. Since it’s available in an array of sizes, lengths and materials, it’s important to understand these differences to choose the best cable wrap for the application.

Popular Applications

Essentially, spiral cable wrap is a tube made from plastic that’s cut in a spiral so that it can wrap easily around cabling in much the same manner as tape. While it’s used in electrical work, spiral wrap can be used in other ways as well. For example, it can be used by bicyclists to keep brake cables neatly organized while also limiting the pressure applied to them.

Other benefits include:

- Allows clamping of cable bundles to robotic components or standoffs

- Manages cables, hoses, tubing or wires in a way that still allows flexibility

- Easy to remove and reuse without tools

- Offers additional protection for cables, hoses, tubing or wiring

- Makes cabling, hoses, tubes or wiring more abrasion resistant

- Multiple colors allow easier identification

- Simple to route or reroute for permitting breakouts from a bundle in any direction

Many industries need to organize cable, hoses or wires and protect them from abrasion. Spiral cable wrap is also commonly used for automated manufacturing systems, electrical control systems, home electronics, public utilities, robotics and a variety of industrial applications.

Materials

While spiral cable wrap made from any material is versatile, certain materials work better for specific applications. Each material offers specific properties that affect performance and flexibility, along with how well it protects bundled cabling.

Black UV Resistant Polyethylene spiral cable wrap can be used for long periods in outdoor environments that receive direct sunlight, so can be used outdoors. Maximum operating temperature for polyethylene is 190°F (88°C), while minimum operating temperature is -76°F (-60°C). Polyethylene spiral wrap can also be made fire-resistant and self-extinguishing, operating best at temperatures between -4°F (-20°C) and 176°F (80°C).

Nylon spiral cable wrap self-extinguishes, while not producing either irritating or toxic byproducts when exposed to open flames or high temperatures. Recommended for confined environments where fire is a possibility, nylon is lightweight and very abrasive-resistant. It also works well over a wide range of temperatures, operating best between -40°F (-40°C) and 250°F (121°C).

PTFE (Polytetrafluoroethylene) spiral cable wrap has an even wider temperature range, and can be used in operating temperatures from -320°F (-200°C). to 500°F (260°C). PTFE is additionally both non-flammable and chemically inert, capable of withstanding industrial environments that utilize toxic chemicals.

M.M. Newman Corporation’s Spiral Cable Wrap

M.M. Newman Corporation’s spiral cable wrap is known by the trade name Heli-Tube®. Our cable wrap can be customized to best fit the application. To meet customer requirements, we’re able to alter color, diameter, length, material, packaging, pitch and wall thickness. Additionally, all our spiral wrap comes in spool lengths of 25, 50 or 100 feet (7.62,15.24 or 30.48 meters).

We can also supply cable wrap that’s either forward or reverse cut to allow either right-handed or left-handed cable bundling. M.M. Newman makes spiral cable wrap from polyethylene, nylon, PTFE (Polytetrafluoroethylene) and fire-resistant polyethylene.

- 17 different colors

- Black ultraviolet (UV) resistant plastic

- Diameters from 1/8 to 1 1/2 inches (3.175 mm to 38.1 mm)

- Diameters from 1/8 to 1 inch (3.175 mm to 25.4 mm)

- Natural or black colors

- Nylon 66, which complies to certain military specifications

PTFE:

- Diameters from 1/16 to 1 inch (1.5875 mm to 25.4 mm)

- Meets RoHS (Restriction of the Use of certain Hazardous Substances in Electrical and Electronic Equipment) compliance

- Natural, black or other colors on request

- Black or white colors

- Diameters from 1/8 to 1 inch (3.175 mm to 25.4 mm)

M.M. Newman Corporation is compliant with the international standard ISO 9001:2015 for quality management, as well as the European Union’s REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS standards. Our spiral cable wrap is also proudly made in the United States. To learn more about our products and the many applications for which they can be used, we invite you to contact M.M. Newman Corporation today.