Tubing encases cables and wires to secure and protect them from a variety of conditions. Different types of tubing are necessary for specific applications. Each is designed and manufactured with material and mechanical properties best-suited for those applications. It may be for protecting cables and wires from wear and abrasion in moving parts, or functioning in a range of environments from mild to harsh in high or low temperatures, or resistance to chemicals, acids, water, heat, and the like.

M.M. Newman Corporation offers a wide selection of tubing to provide the necessary material and mechanical properties for your application. Whether it’s tubing of varying dimensions and thicknesses, corrugated or convoluted, or heat shrink tubing, M.M. Newman Corporation has the tubing options to meet your application requirements. Choosing the right tubing for your application has never been easier:

PTFE Extruded Tubing

PTFE extruded tubing is a fluoropolymer material choice for applications in many environments. Known for its non-conductive, dielectric properties, PTFE is a choice material for high electrical fields and insulating electronic components. PTFE is water and heat resistant, resists chemical and acid corrosion, and has excellent lubricity. Perhaps its best-known property is its low frictional coefficient, meaning that nothing sticks to it, which is why it lines many pots and pans in kitchens around the globe under the name Teflon.

Because of its superior properties, PTFE has many general applications in such diverse industrial sectors as chemical, automotive, aerospace, electrical, medical, manufacturing, and pharmaceutical industries. M.M. Newman Corporation’s PTFE extruded tubing is offered in varying sizes and materials—PTFE Industrial Heavy Wall Tubing, Standard Wall PTFE Electrical Insulation Tubing, and Thin Wall PTFE Electrical Insulation Tubing.

Tubing dimensions are specified as light, thin, standard, and heavy-walled. Working temperature ranges of PTFE tubing are from -454°F to 500°F (-270°C to 260°C). Due to its non-conductive and insulating properties, the tubing is well-suited to protect wires and cables in harsh working environments. Depending on the material applications, extruded tubing can also be manufactured with such other fluoropolymers as FEP or PFA.

M.M. Newman Corporation’s PTFE extruded tubing meets or exceeds ASTM D 3295, AMS 3655, AMS 3653 and MIL-I-22129 industry standards.

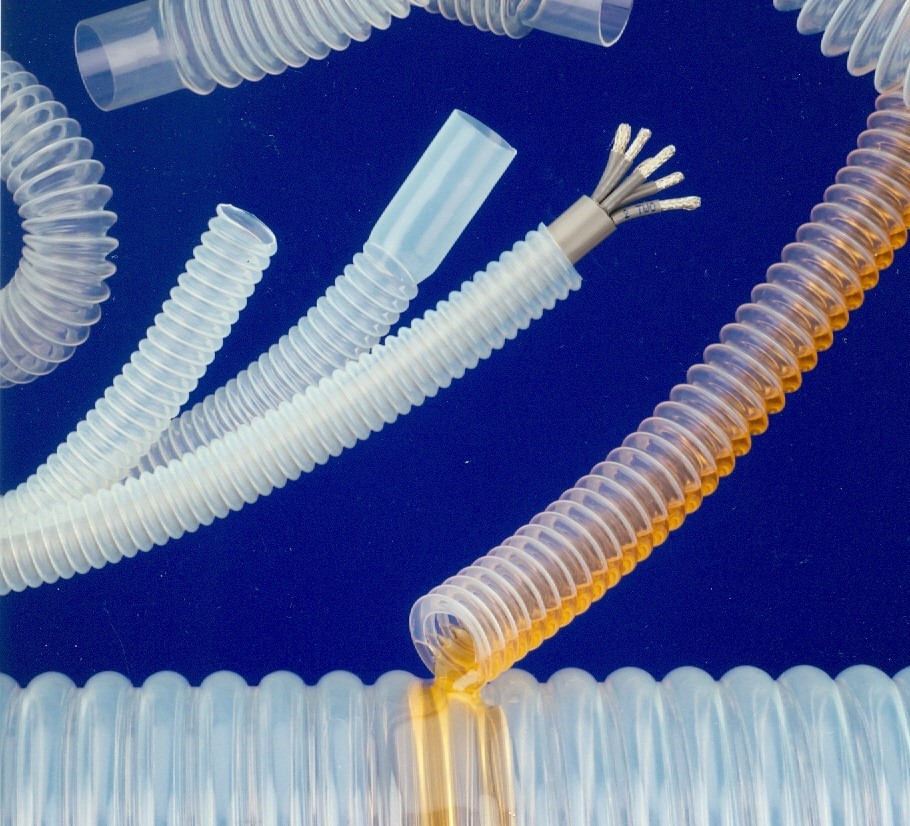

FEP Corrugated Tubing & PTFE Convoluted Tubing

M.M. Newman Corporation’s FEP corrugated tubing & PTFE convoluted tubing is designed to protect wire and cables subject to severe working conditions. The different tubing is available in various configurations to meet the select needs of many applications. The fluoropolymer material is chemically inert, non-flammable and acid resistant, and with its low coefficient of friction makes it ideal for transporting most corrosive materials.

Whether application needs require corrugated or convoluted, tubing can also be extruded from PFA. Inner diameter ranges from 0.25″ to 3″ with plain or cuffed ends. Material selection depends on temperature ratings, flexibility and kink resistance needs. For example, FEP tubing material rates up to a maximum continuous operating temperature of up to 93°C (200°F) and can bend 90° without reducing the inside diameter of the tube. PTFE convoluted tubing, with continuous operating temperatures up to 450°F, offers exceptional chemical and acid resistance to nearly all natural and industrial solvents.

M.M. Newman’s corrugated and convoluted tubing can be custom made to meet the most challenging application needs. These high-quality tubing products are commonly utilized by the aerospace, automotive, electrical and medical industries for automation, laboratory equipment, and instrumentation applications.

Heat Shrink Tubing

Heat shrink tubing is a skin-tight wrap and protective barrier for wires and cables. M.M. Newman offers two heat shrink tubing materials, PVC heat shrink tubing and flexible polyolefin heat shrink tubing, for industrial and military applications.

In wrapping applications that require a high degree of flexibility, with smooth, tight-fitting insulation, PVC heat shrink tubing is recommended. It has exceptional mechanical and dielectric properties, is moisture, sunlight, and fungus resistant, as well as most chemicals and oils, with a low shrink temperature of less than 200°F (93°C). This tubing securely insulates and protects wires and cables without damage to adjacent or enclosed components.

With its superior combination of chemical, electrical, and physical properties, flexible polyolefin heat shrink tubing is ideally suited for securing cables and wires under the harshest conditions. It is rated for up to 275°F (135°C) of continuous operation with short bursts of elevated temperatures up to 572°F (300°C). Lightweight and flexible, applications include cable and wire harness coverings, component packaging, and as a fire-resistant covering.

Heat shrink tubing supports a wide range of applications in nearly every industry. Both PVC and polyolefin meet all industry standards, are manufactured in clear as well as standard colors. Customized, hot stamp printing is available for branding or easy identification.