Regardless of the industry you’re in, you probably work with, at some capacity, cables and wires. Whether it’s the inevitable tangle of computer wiring or daily abrasion to your industrial hoses and tubing, there are many common frustrations businesses experience that can be solved with a simple solution: spiral cable wrap from M.M. Newman Corporation.

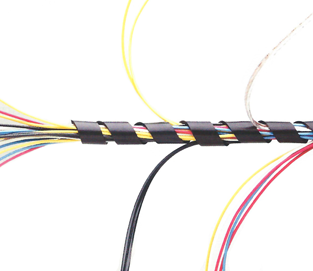

Heli-Tube® spiral cable wrap holds bundles of wires, hoses and cable securely, allowing flexibility for the wires while still keeping them organized and protected. With cable wrap available in a wide variety of materials and sizes, we have the options you need to protect your cables, hoses and wires. Here, we cover three of the main factors to consider when choosing cable wrap from M.M. Newman Corporation.

Consideration #1: Properties and Materials

Which material is right for your application? What properties should you take into consideration when selecting spiral cable wrap?

Not all spiral cable wrap is created equally. It’s important to note that we have a large variety of materials to choose from based on your cable wrap needs, each with its own unique qualities. All of our spiral wrap is UL Listed and RoHS Compliant.

Polyethylene – Ideal for General Applications

Ideal for most general applications, polyethylene is a low-cost material that is surprisingly powerful. It’s highly abrasion-resistant and not affected by most solvents, making it suitable for nearly all industries. We offer a few different types of polyethylene spiral cable wrap with varying properties. Natural polyethylene is a great option for your standard, daily cable wrap usage, available in a variety of colors to be used for identification, coding, and decoration. UV-resistant polyethylene is ideal for outdoor use, as it can be used in direct sunlight for extended periods of time, while fire-resistant polyethylene is suitable for applications that require a self-extinguishing material.

Nylon – Optimal for Enclosed Environments

Nylon is lightweight, extremely abrasion-resistant, and operates over a wide temperature range. Nylon is self-extinguishing and doesn’t produce any toxic or irritating byproduct, even when exposed to open flame or excessive operating temperatures. Given that, it’s recommended for use in enclosed environments, especially where there is the possibility of fire. There is also black nylon, which offers the benefit of an ultraviolet absorber, allowing for direct sun exposure for extended periods of time.

PTFE – Non Flammable and Perfect for High Temperatures

Natural PTFE features the widest operating temperature range of any material we offer, from -450 degrees Fahrenheit to 500 degrees Fahrenheit. PTFE is chemically inert, UV-resistant, and non-flammable, making it a safe option for your most demanding spiral cut tubing needs.

Consideration #2: Dimensions

What size cable wrap will you need?

When choosing the correct spiral cable wrap for your needs, there are several factors that come into play. We offer a variety of sizes based on type of cable wrap material, so you have flexibility when deciding what’s best for you. The dimensions you should keep in mind when ordering:

- Diameter of the wires or bundle that you are covering

- Bundle range of the spiral wrap

Depending on the material you’re in the market for, our spiral wrap is available from 1/16” to 1 ½” OD.

Consideration #3: Quantity, Packaging Options and Additional Services

How many feet do you need, how do you want it packaged, and how soon do you need it?

Even after you’ve decided on the spiral cut cable wrap you plan to purchase, there are still factors you may need to take into consideration, quantity, packaging, and shipping.

The standard packaging for our spiral cut tubing is 100 feet per spool for most sizes. We are also happy to accommodate and quote special requests such as cutting the spiral wrap to custom lengths, or 25 ft and 50 ft spools. Working with your release schedules, custom labeling, palletizing, and packaging for overseas shipments can be provided by request to help make the ordering process seamless and easy.

Spiral cable wrap offers numerous advantages, from increasing cable lifespan to reducing the amount of maintenance and repairs needed for wires, cables, and hoses. Designed to withstand extreme conditions, from severe cold and heat to solvents and oils, our Heli-Tube® cable wrap isn’t only a quick fix for unruly cable hazards or hose protection – it’s an inexpensive way to keep your business running smoothly.

Look no further than M.M. Newman Corporation as your trusted spiral cable wrap supplier. We are ISO 9001:2015 Certified, and totally committed to customer satisfaction. Contact our team to learn more about our product selection today!